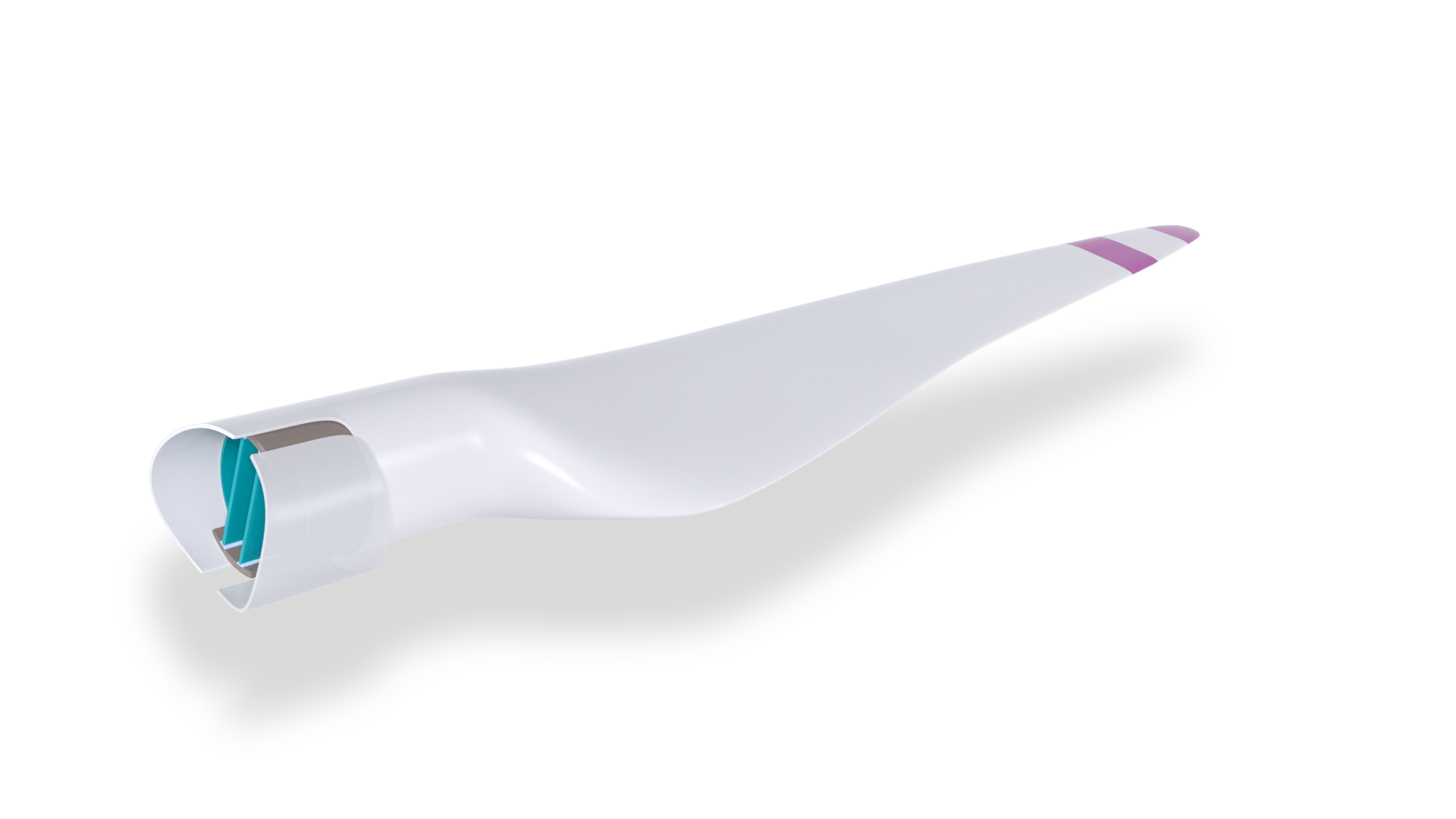

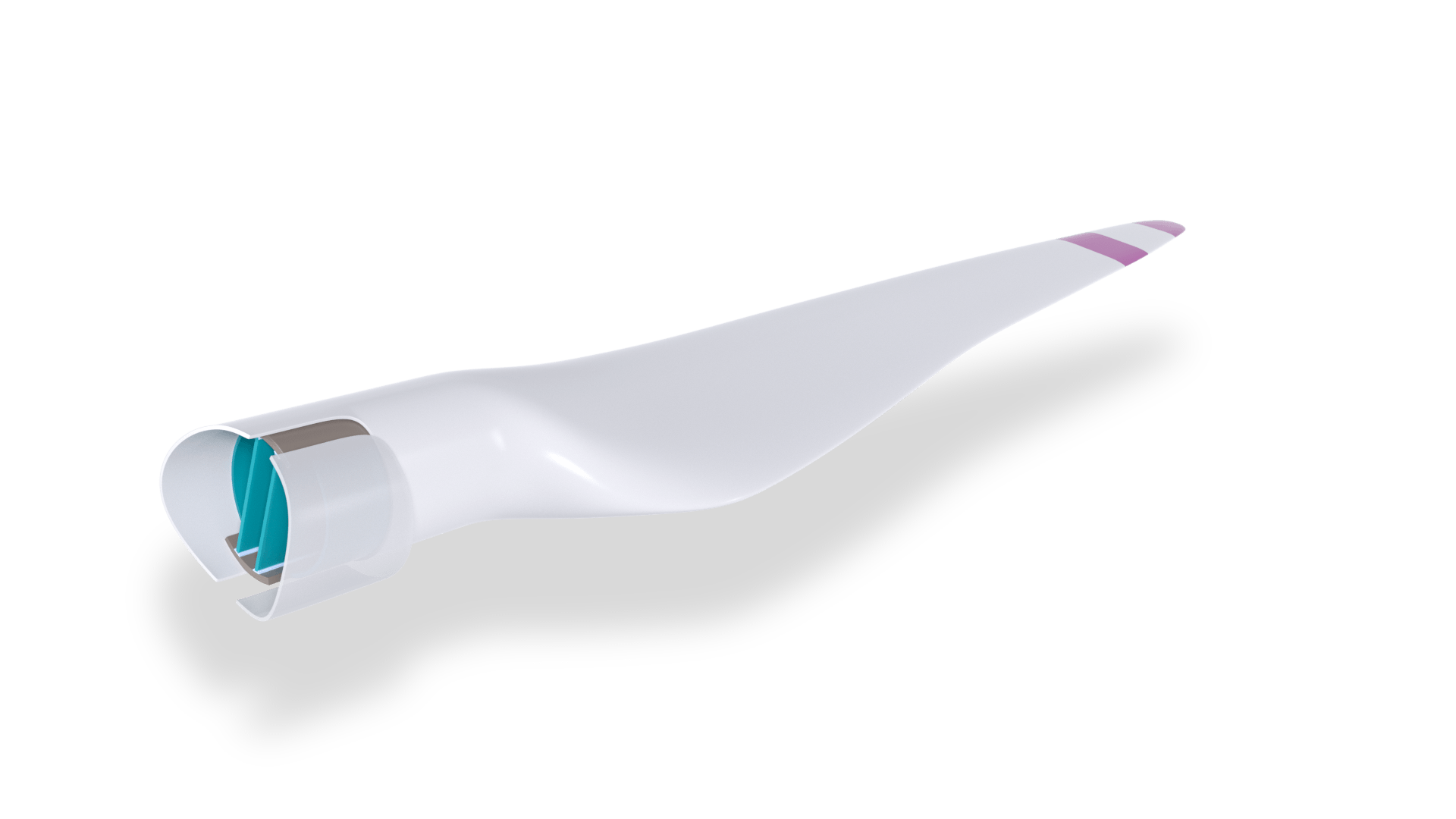

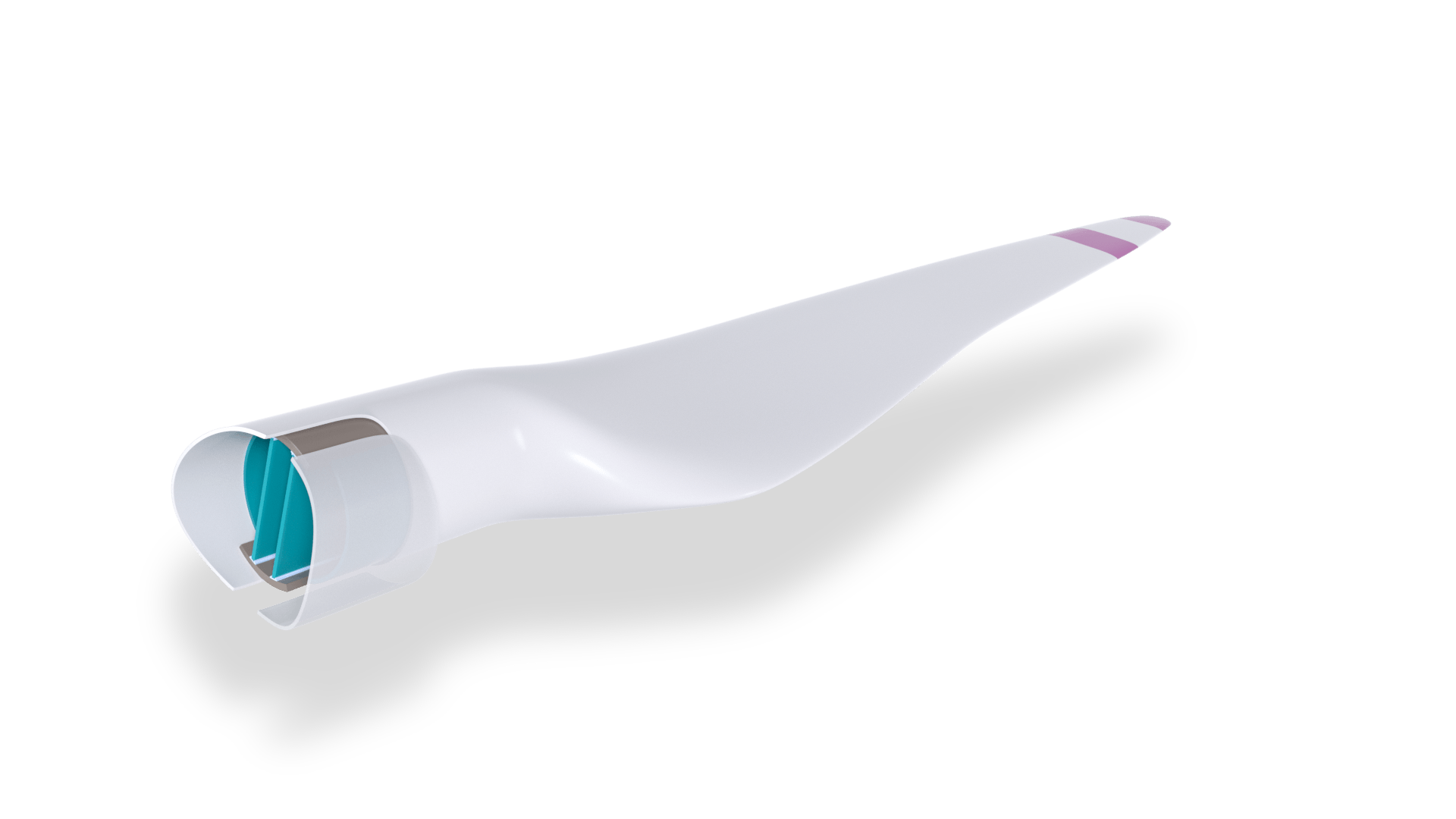

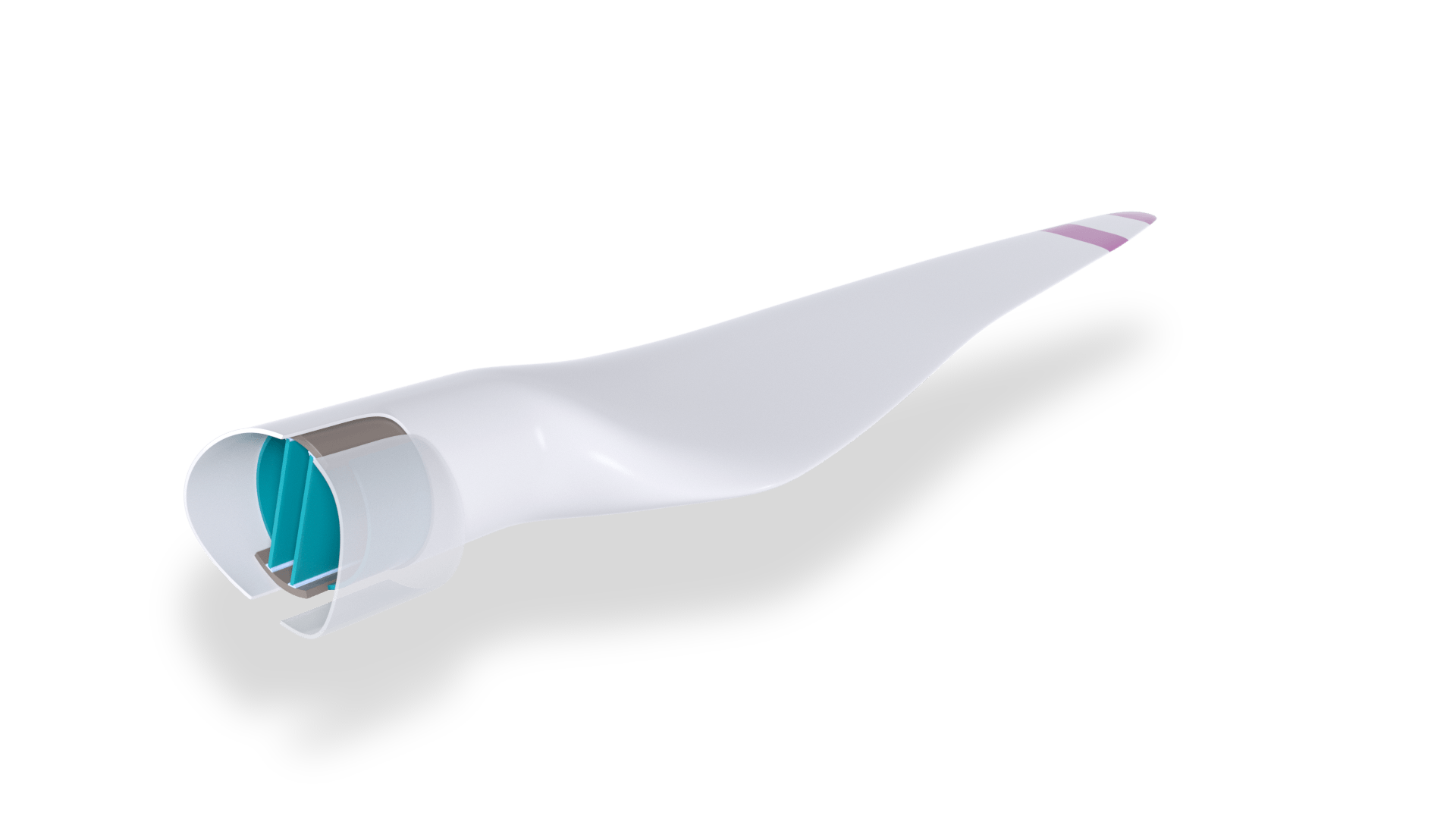

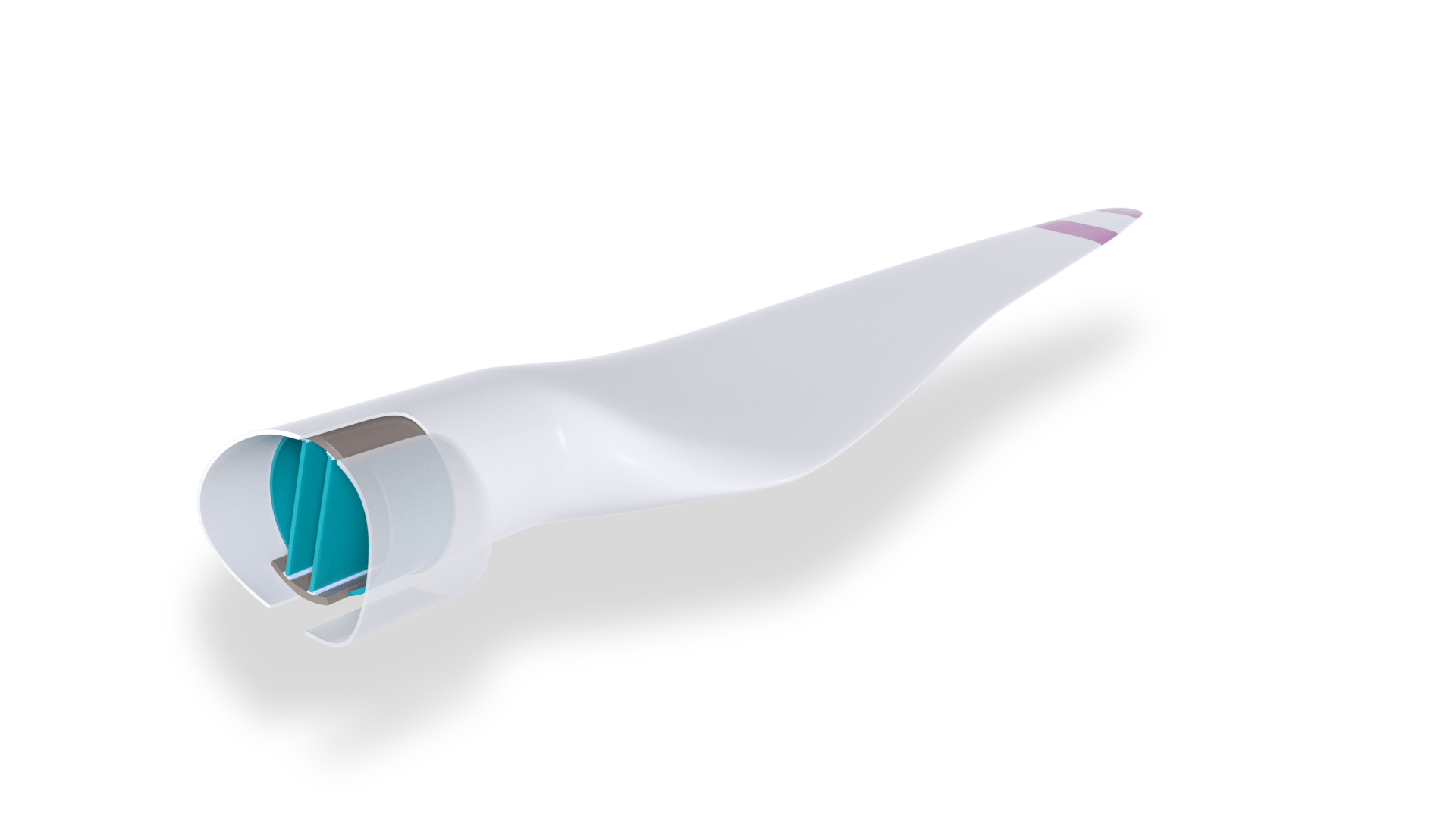

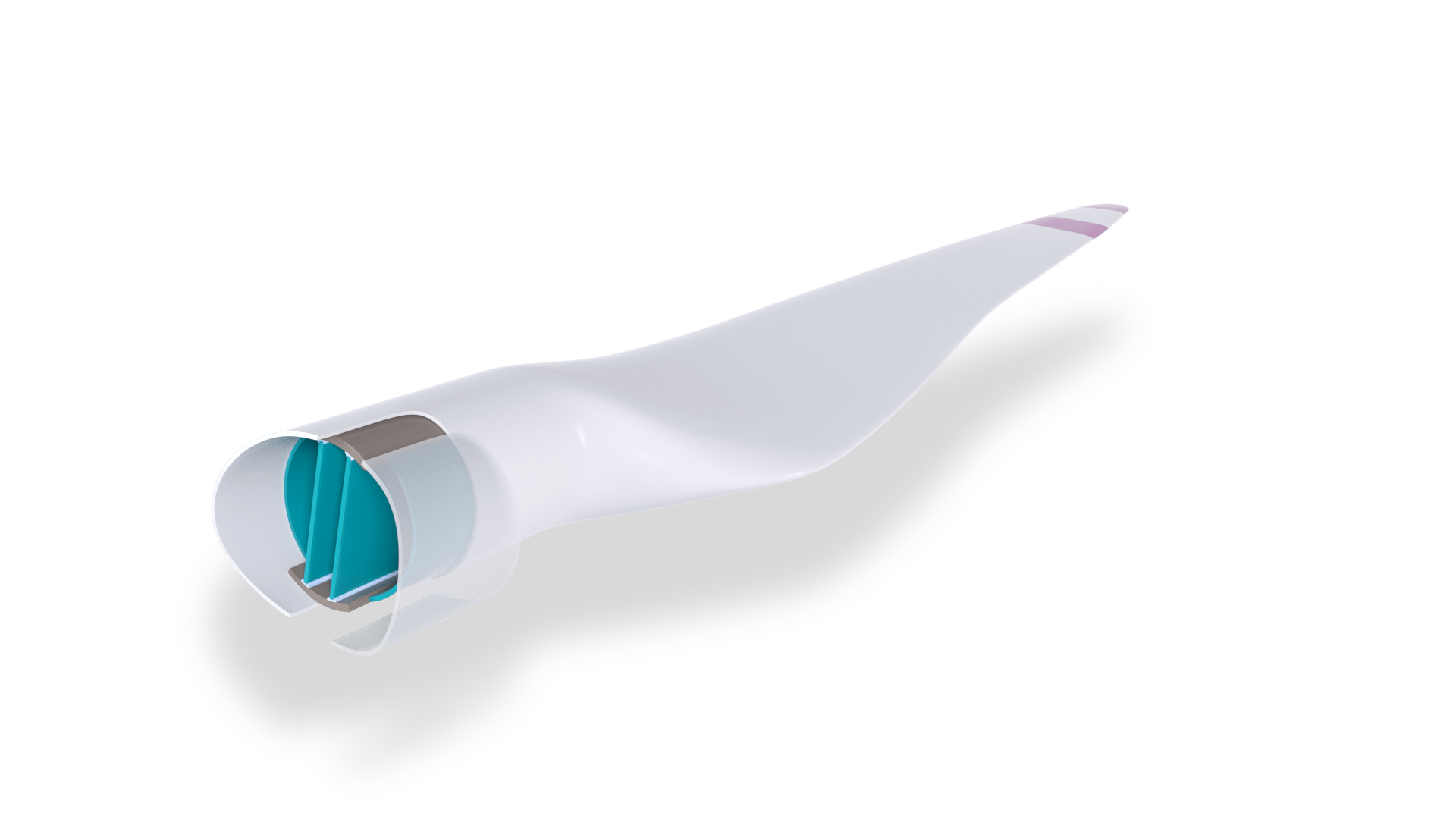

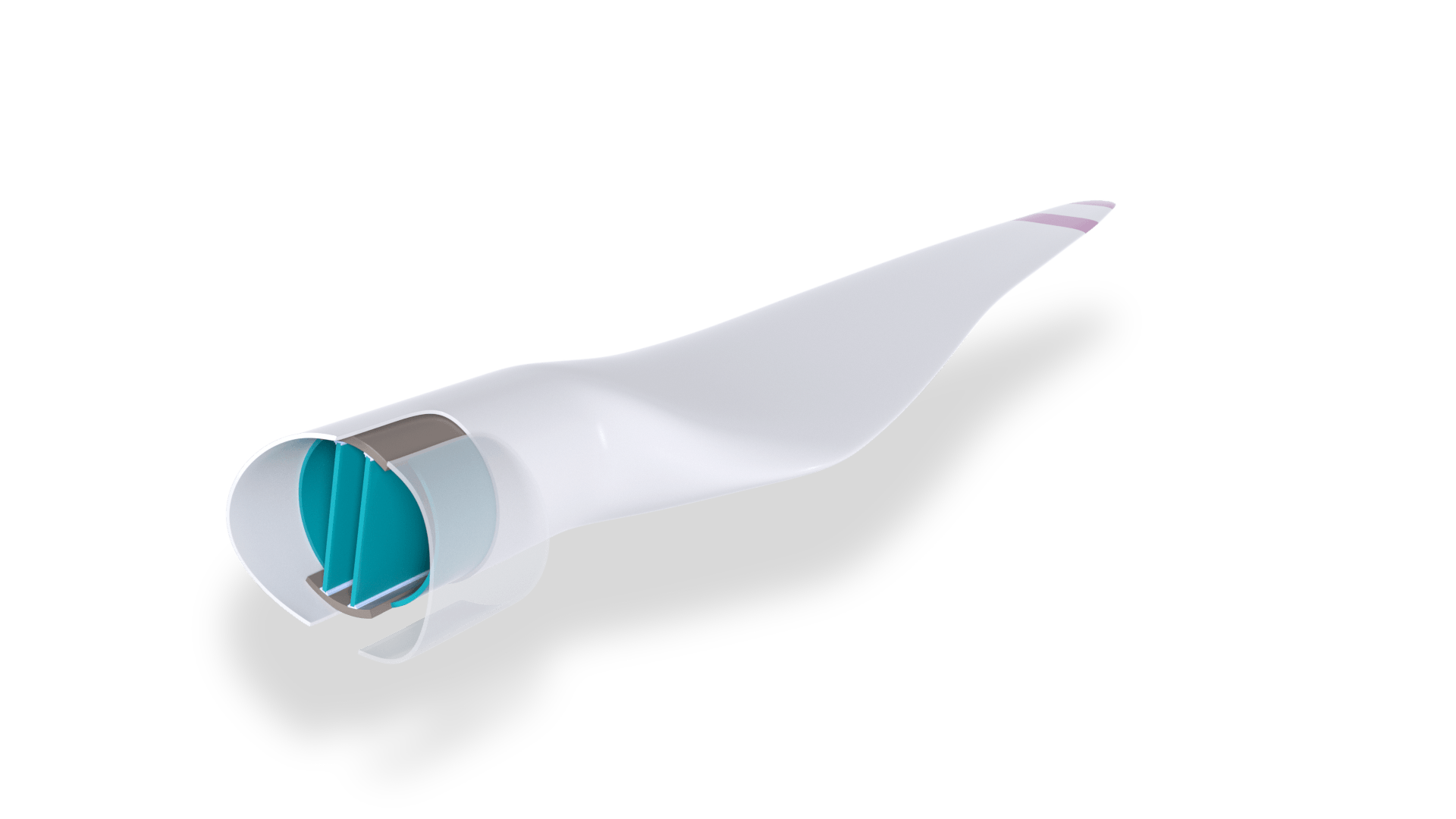

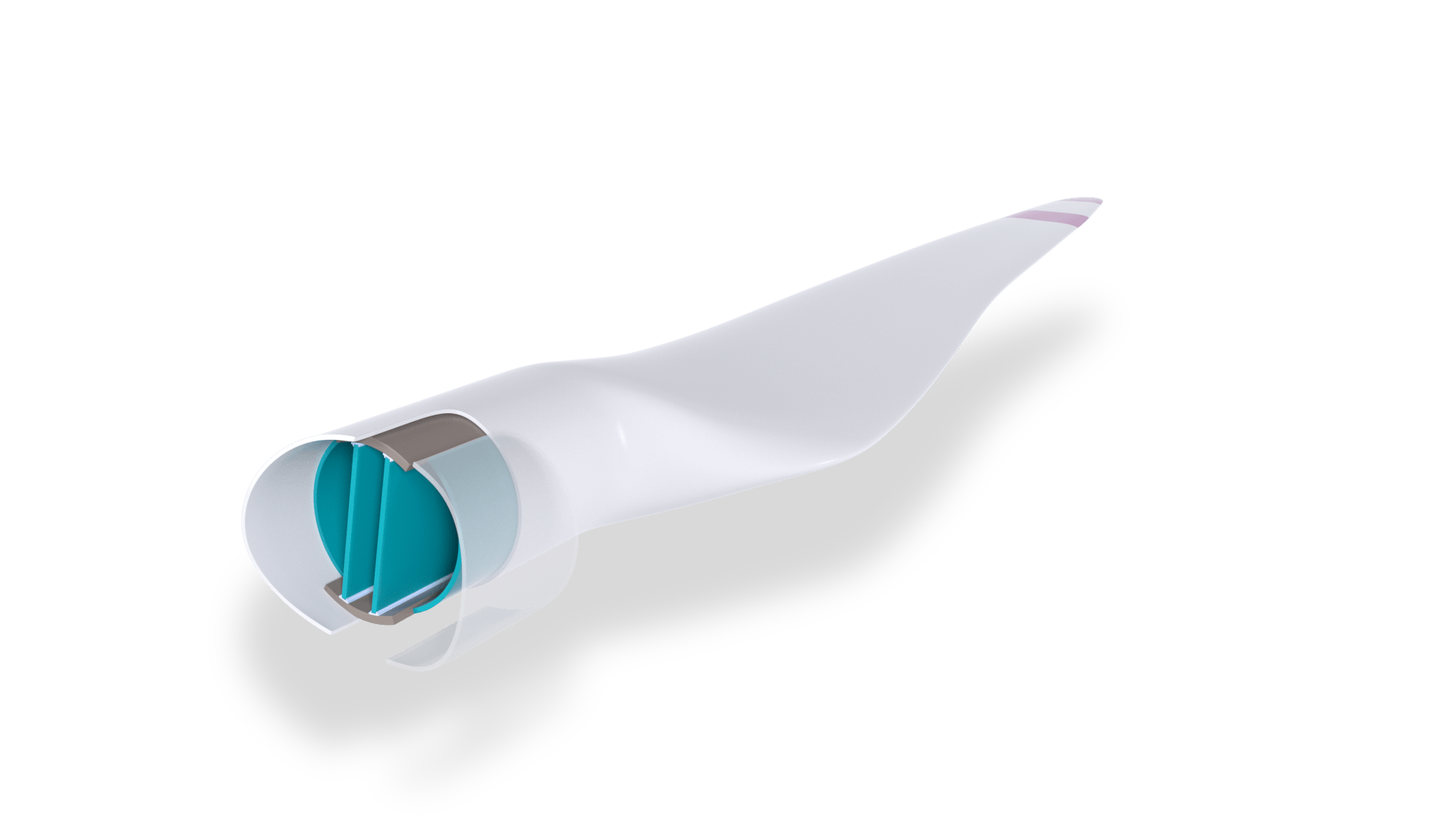

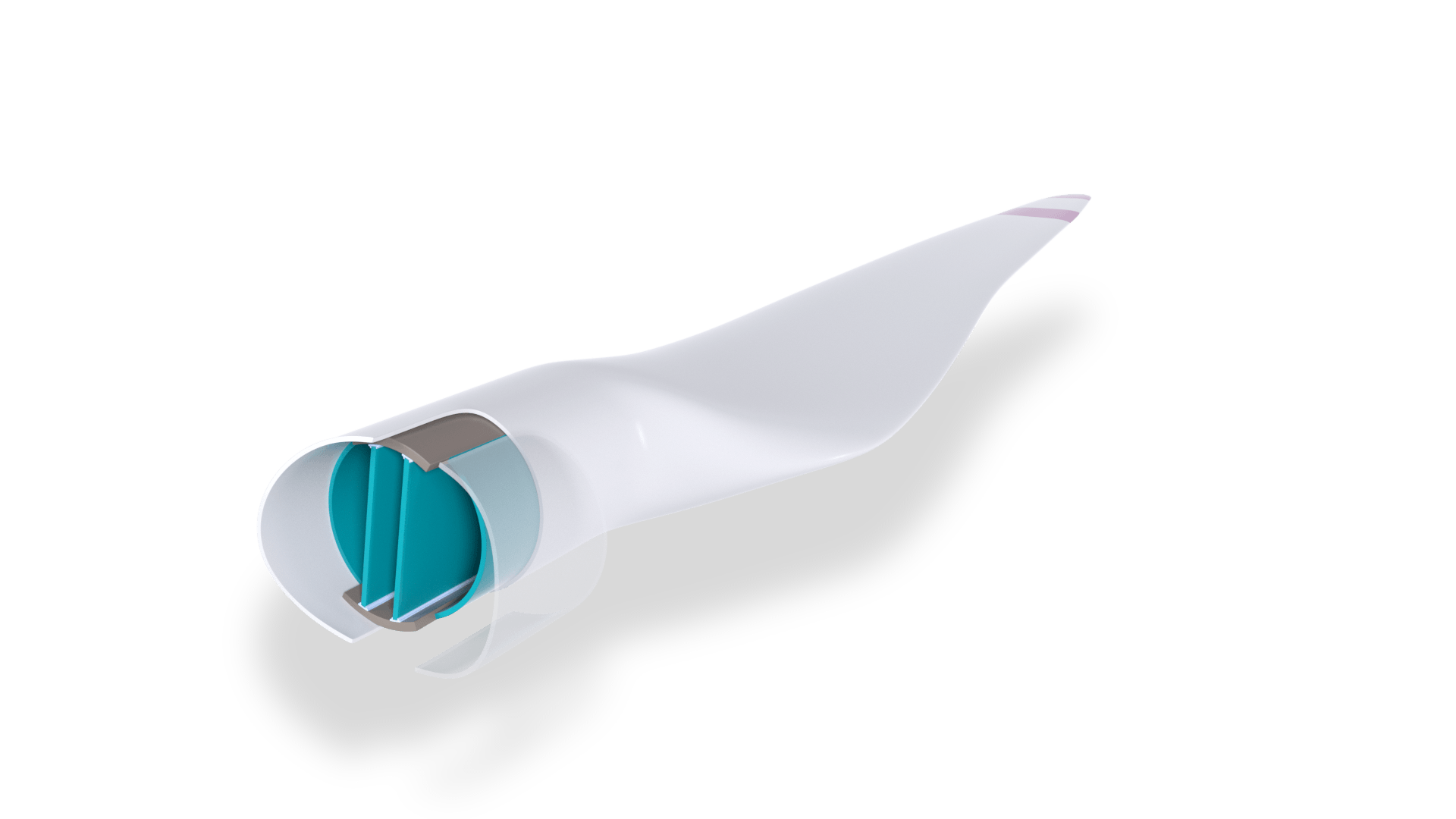

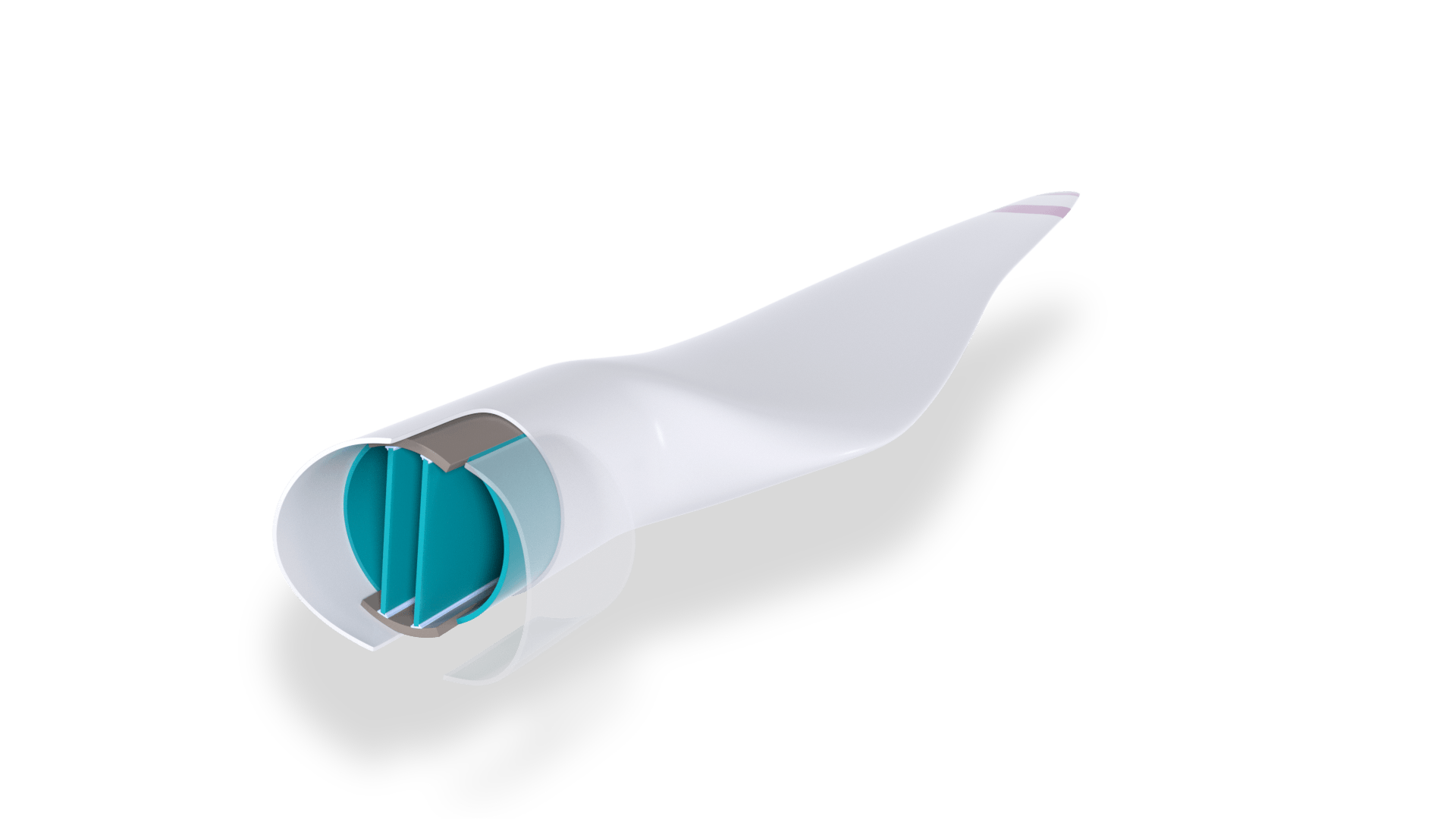

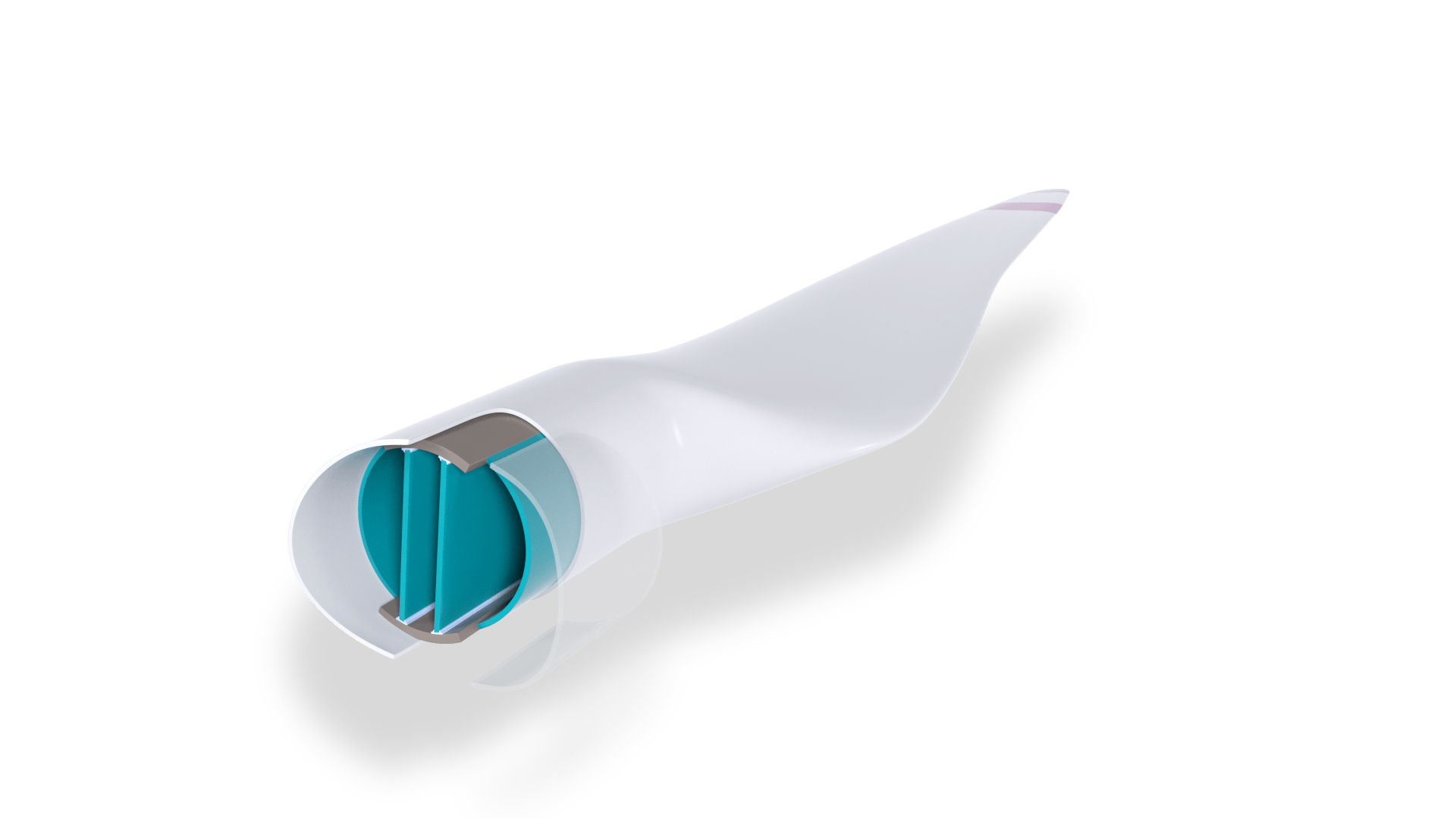

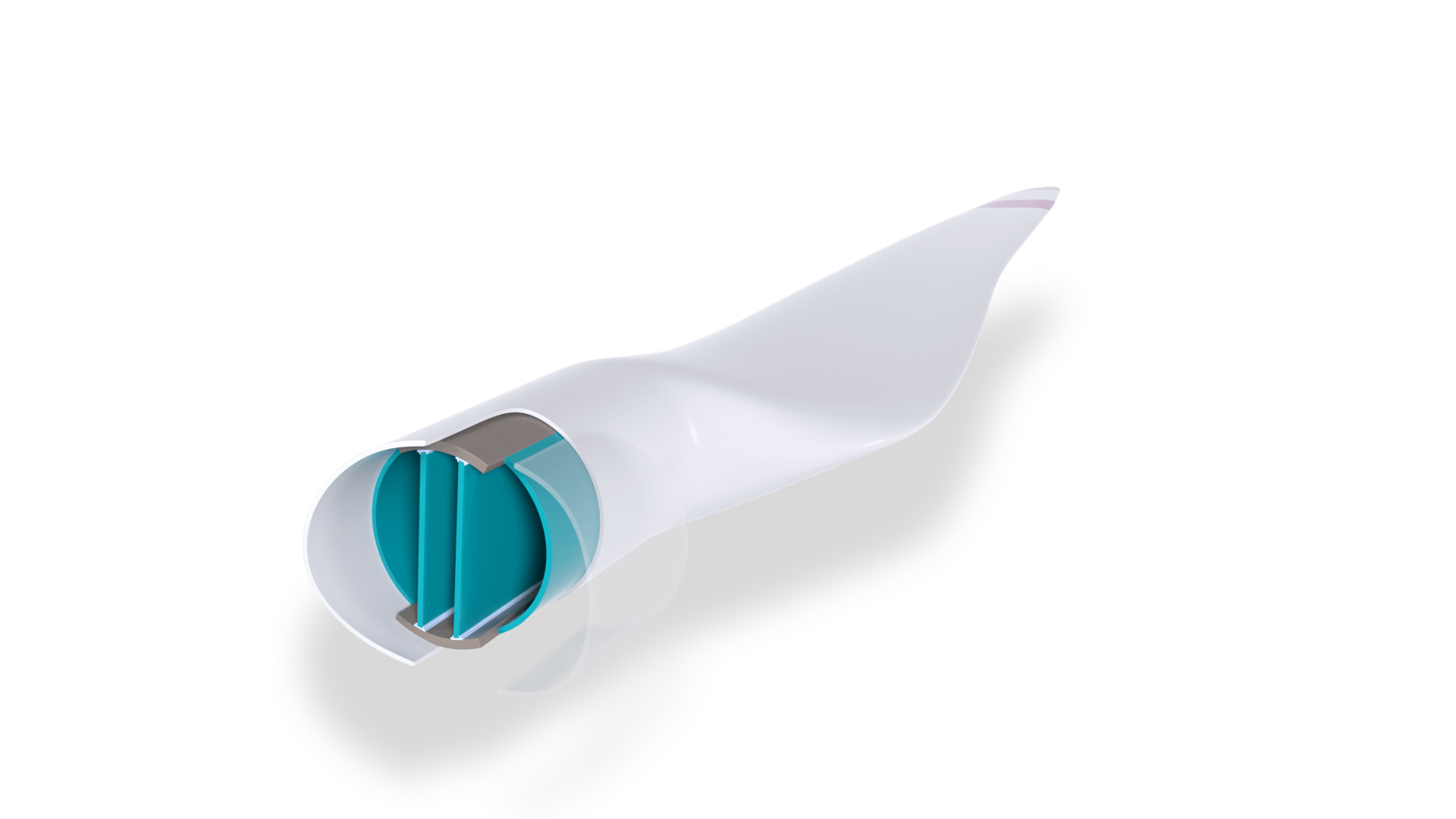

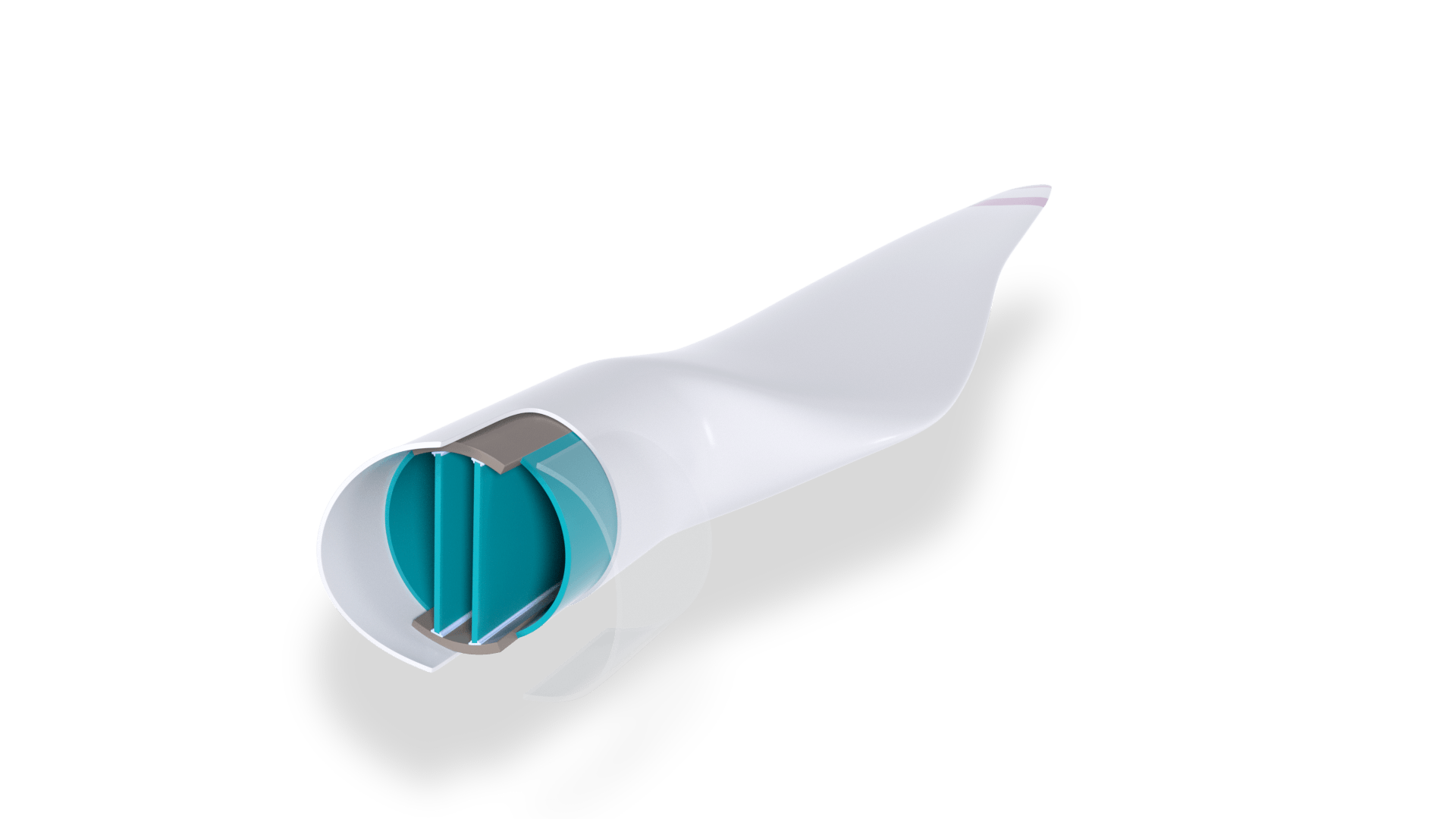

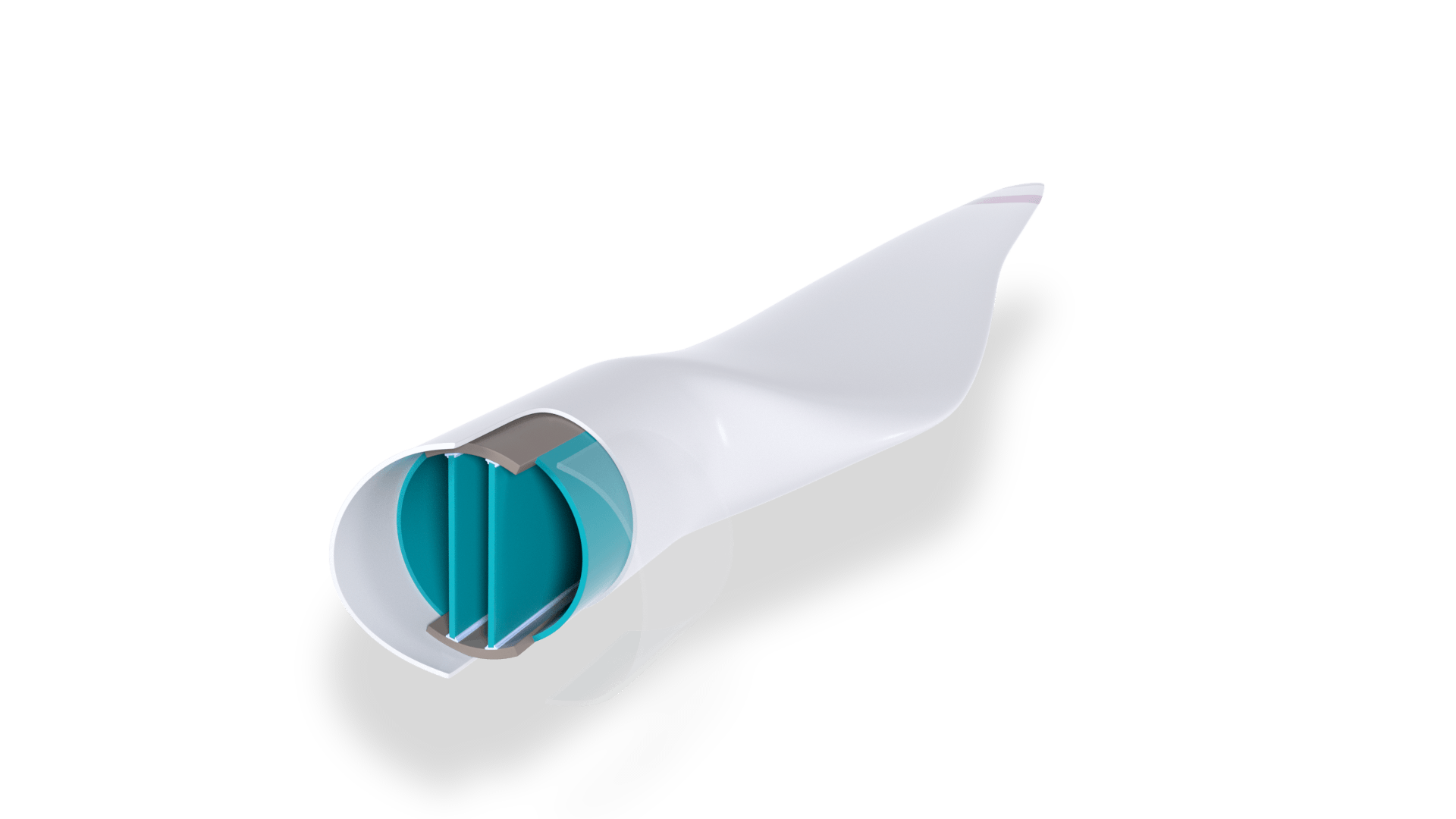

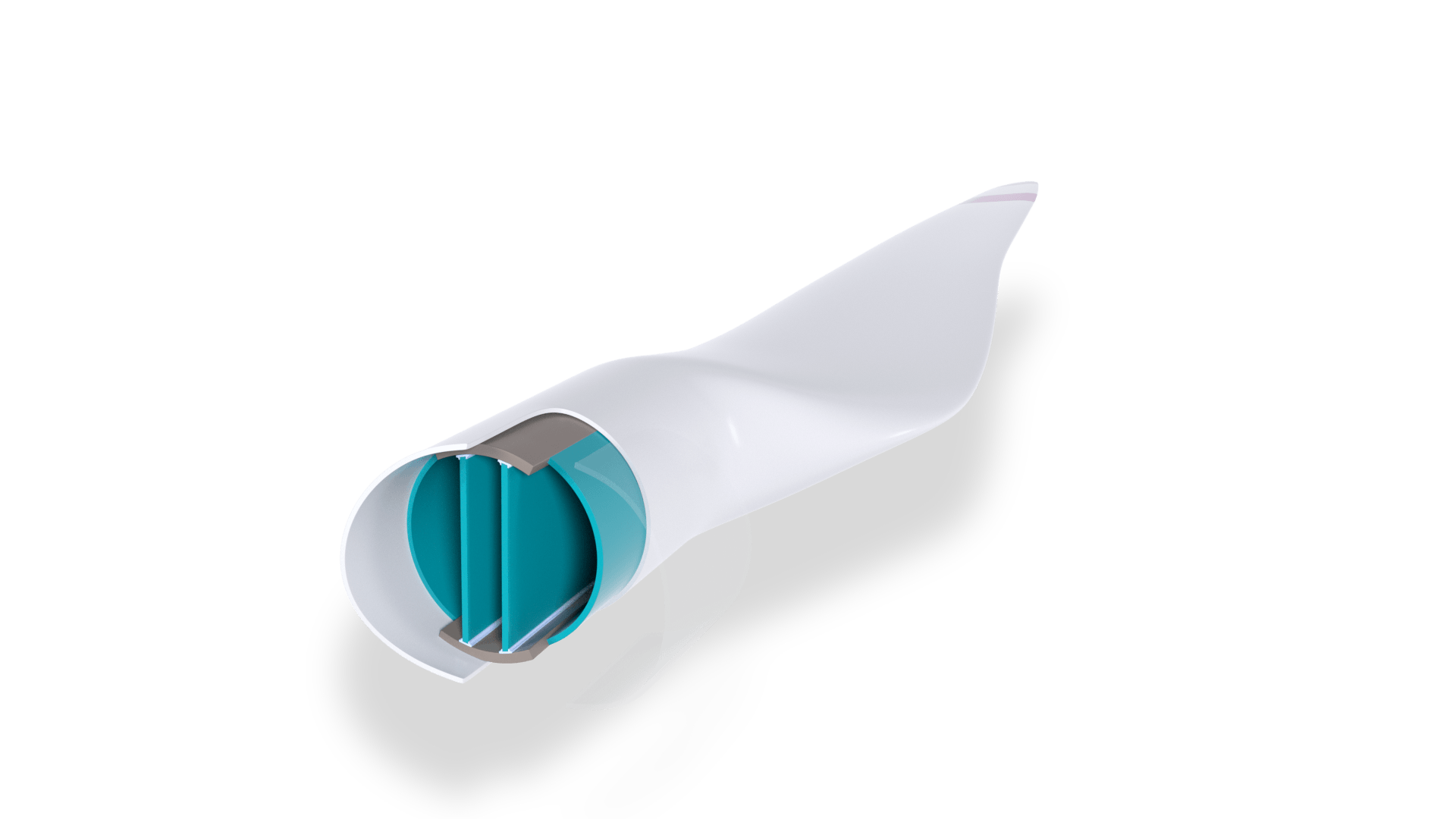

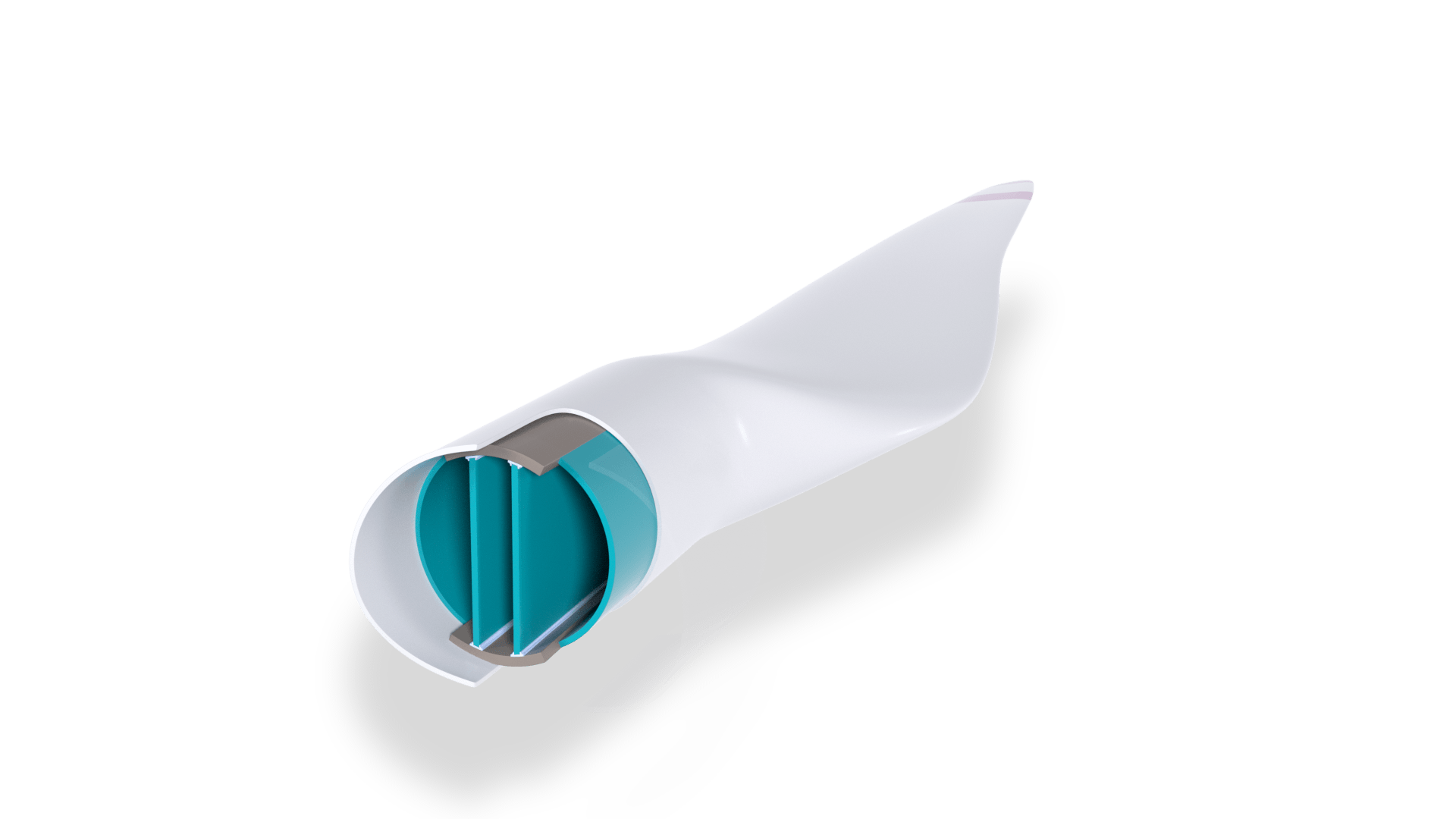

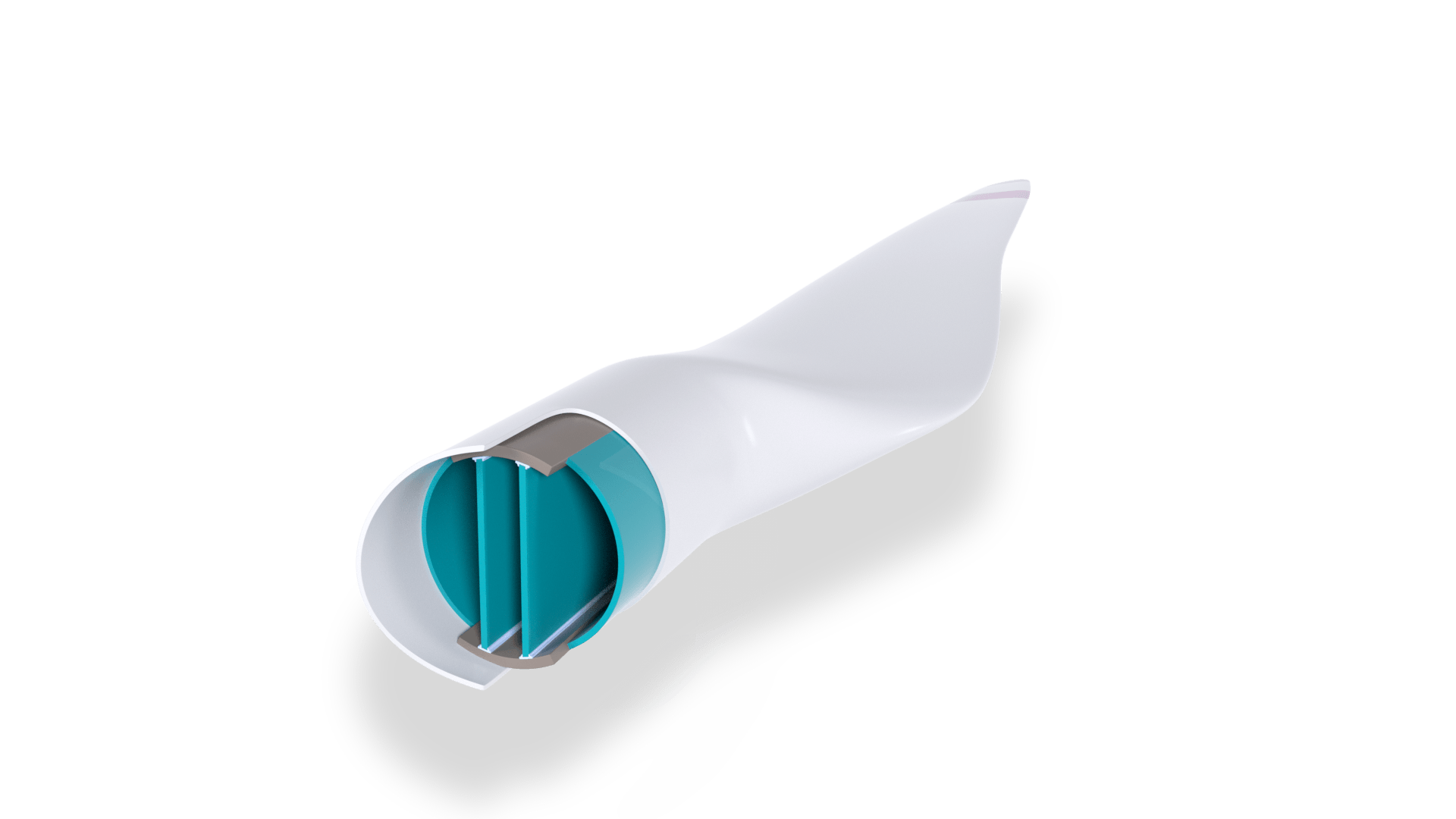

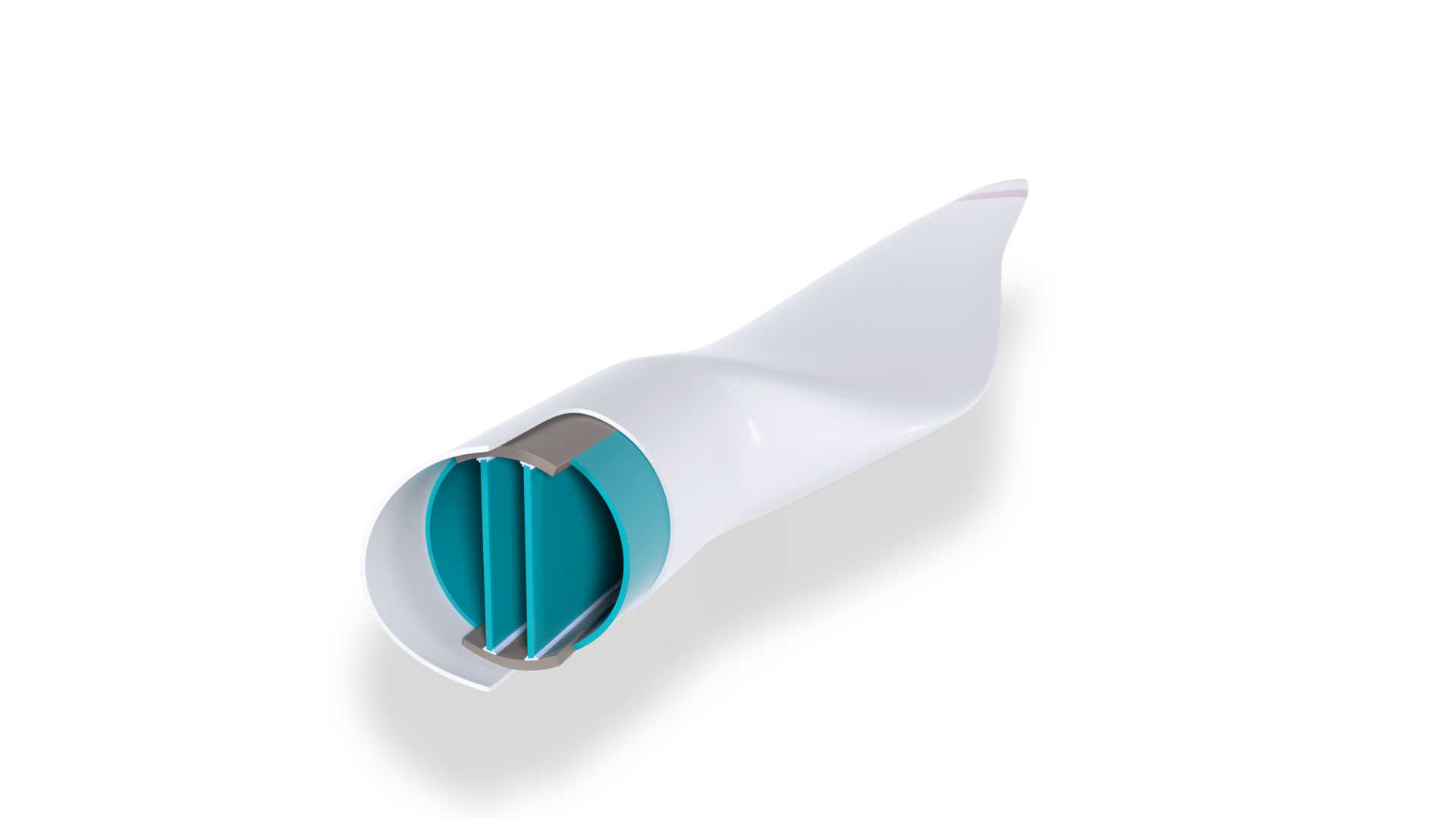

help wind turbines

to turn and last a lifetime

and NANOPOX®

VESTAMIN® IPD gives rotor blades strength and durability

State-of-the-art crosslinker for liquid epoxy matrix technology in rotor blades. It's also essential for the adhesive and provides reactivity in the curing process and high mechanical strength for the composite.

further informationANCAMIDE® for structural epoxy adhesives to enable even longer rotor blades

High-performance curing agents that extend gel times to enable longer bond line lengths for the manufacture of even larger rotor blades, overcoming future production challenges.

further informationVESTANAT® improves the rotor blade's resistance to weathering

Cycloaliphatic polyisocyanates used as gel coats, coatings or in-mold coatings for rotor blades to optimize drying and chemical resistance. They also enhance weather resistance and durability.

further informationROHACRYL™ is the newcomer to our performance foam family

The acrylic chemistry based structural foam is a core material solution that has excellent mechanical properties and is thermally stable. It is lightweight, easy to shape and has no impact on the environment.

further informationAEROSIL® for better coatings and adhesives

Effective thixotropes guarantee the stability of rotor blade adhesives during processing. In surface coatings, it supports good opacity of lacquers and improves scratch resistance.

further informationALBIDUR®, ALBIPOX® and NANOPOX® improve fatigue performance and tear resistance toughness

Modified resins enable long-lasting components, whether as tackifiers for fabrics or tougheners for paste adhesives and infusion resins. They improve rotor blade service life by providing exceptional fatigue-resistance properties.

further informationDYNASYLAN® for enhanced durability

Coupling agents that give lasting connections between glass fiber mats and resins to optimize the stability of composites. They improve adhesion, minimize moisture sensitivity and protect glass fibers.

further informationNANOPOL® significantly improves tear resistance, fracture toughness and modulus

Nanoparticles protect rotor blades against salt and sand. This protection pays off for wind farm operators as it takes two days to replace an offshore rotor blade at sea.

further informationVISIOMER® methacrylates - low volatile reactive diluents

Specialty methacrylates are used as reactive diluents or crosslinkers in unsaturated polyester resins and vinyl ester formulations, particularly beneficial for full, or partial substitution of styrene in composite resins.

further informationVISIOMER® methacrylates - low volatile reactive diluents

Specialty methacrylates are used as reactive diluents or crosslinkers in unsaturated polyester resins and vinyl ester formulations, particularly beneficial for full, or partial substitution of styrene in composite resins.

further information